3D printers have become a product that is suitable for the mass market. As they have become easier to use and cheaper, many people buy a 3D printer for home use to print individual parts themselves.

When choosing, an important question then arises for the beginner:

Which 3D printer is the right one for me?

In this article, we will first discuss which printing methods are available and what the advantages and disadvantages of FDM or SLA printing are.

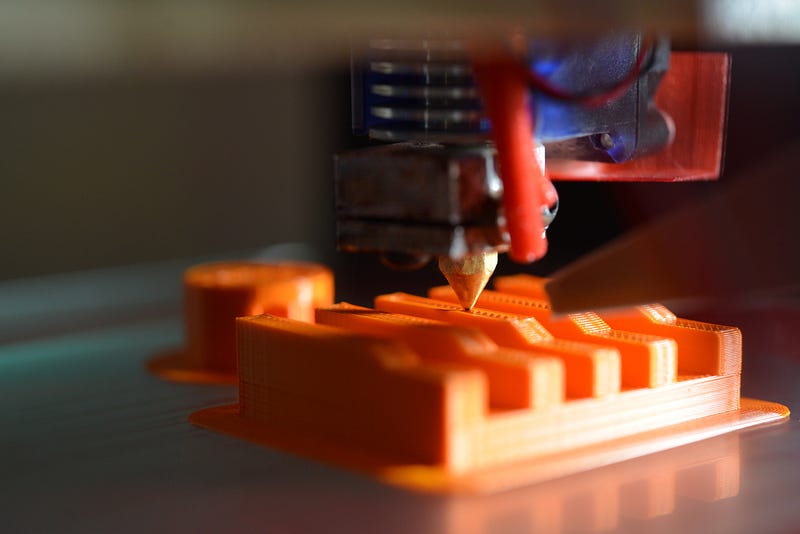

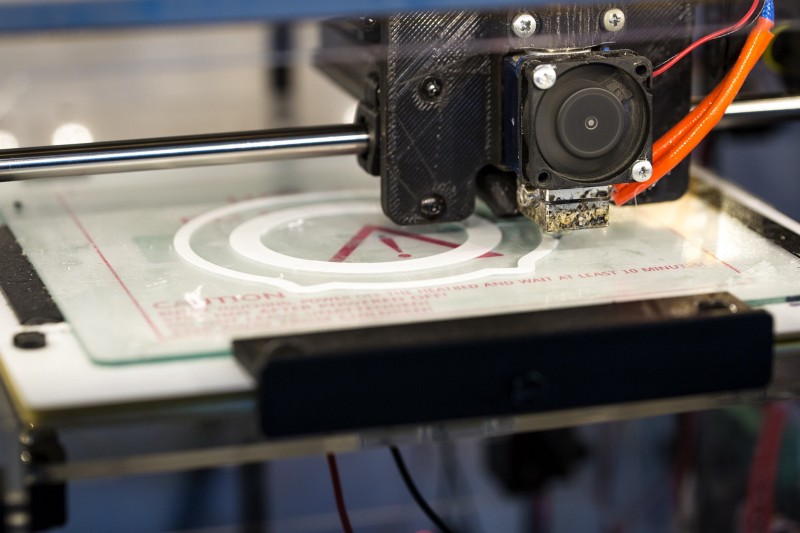

Fused Deposition Modeling (FDM) Printer

The most commonly used printing method in the hobby sector is the FDM printer. This is based on the principle that thermoplastics are melted and applied layer by layer on a print bed to gradually create the 3D model.

Advantages

- relatively fast printing possible

- Low cost

- Relatively durable

- rework is only necessary if a support structure was used

Disadvantages:

- only medium production precision

- depending on the printer, more or fewer grooves are visible in the print (individual layers)

Stereolithography (SLA) Printer

An SLA printer is based on the principle that a plane of print is made by illuminating and curing a liquid (epoxy resin) in just the right places.

Advantages:

- high manufacturing precision

- smooth surfaces

- high impact resistance

Disadvantages:

- rather small printing range in the lower price segment

- slow manufacturing process

- relatively expensive

- work with toxic epoxy resins

- rework necessary (final curing in UV chamber)

Comparison of the FDM and SLA printer

The comparison shows that an FDM printer is inferior to an SLA printer in terms of print quality and precision. You will never get close to the precise and smooth surfaces of an SLA printer with an FDM printer. On the other hand, in the low to mid price range for SLA printers, there is little or no way to buy a really large print area.

Even if you should not necessarily pay attention to the time in 3D printing, because it always takes a relatively long time to print a large component here is short info about it. The speed of the printer varies depending on the component, but the FMD printer is usually faster. The most important difference is that an SLA printer always takes the same amount of time and you can’t speed it up. With an FDM printer, for example, you can choose a longer print time and thus higher print quality, or a very low print time, with reduced print quality.

Which printer is right for you?

To decide which printer, or printing method, is right for you, it shows what you want to implement with it. In comparison, there are clear differences between the two printing methods, which you can use as a guide.

If you want to quickly produce individual prototypes that are functional but do not have to look 100% precise or beautiful, you should first look at an FDM printer. Even if it is foreseeable that you want to print objects larger than 20cm, there is no way around an FDM printer. If you disregard the print quality, you always get more print sizes for the same money as an FDM printer.

However, if the intended use of your 3D printer is for small parts and good print quality, you should go for an SLA printer. An example of this would be the printing of figures or similar. With an FDM printer, these would always be somewhat uneven and grooved due to the relatively large layers on top of each other. This can be seen (relatively exaggerated) in the following picture.

With an SLA printer, these grooves are barely noticeable and you have a relatively smooth surface over the entire print.

In summary, it can be said that an SLA printer is always useful if no very large parts have to be printed, but very good print quality and precision should be achieved. If the print quality can be compromised and a large print area is desired, an FDM printer should suffice due to the lower price compared to the print size.

If you like my work, feel free to check out my other articles on similar topics.

Schreibe einen Kommentar